Collection

Heritage

“A concerted effort to preserve our heritage is a vital link to our cultural, educational, aesthetic, inspirational, and economic legacies - all of the things that quite literally make us who we are.”

Steve Berry

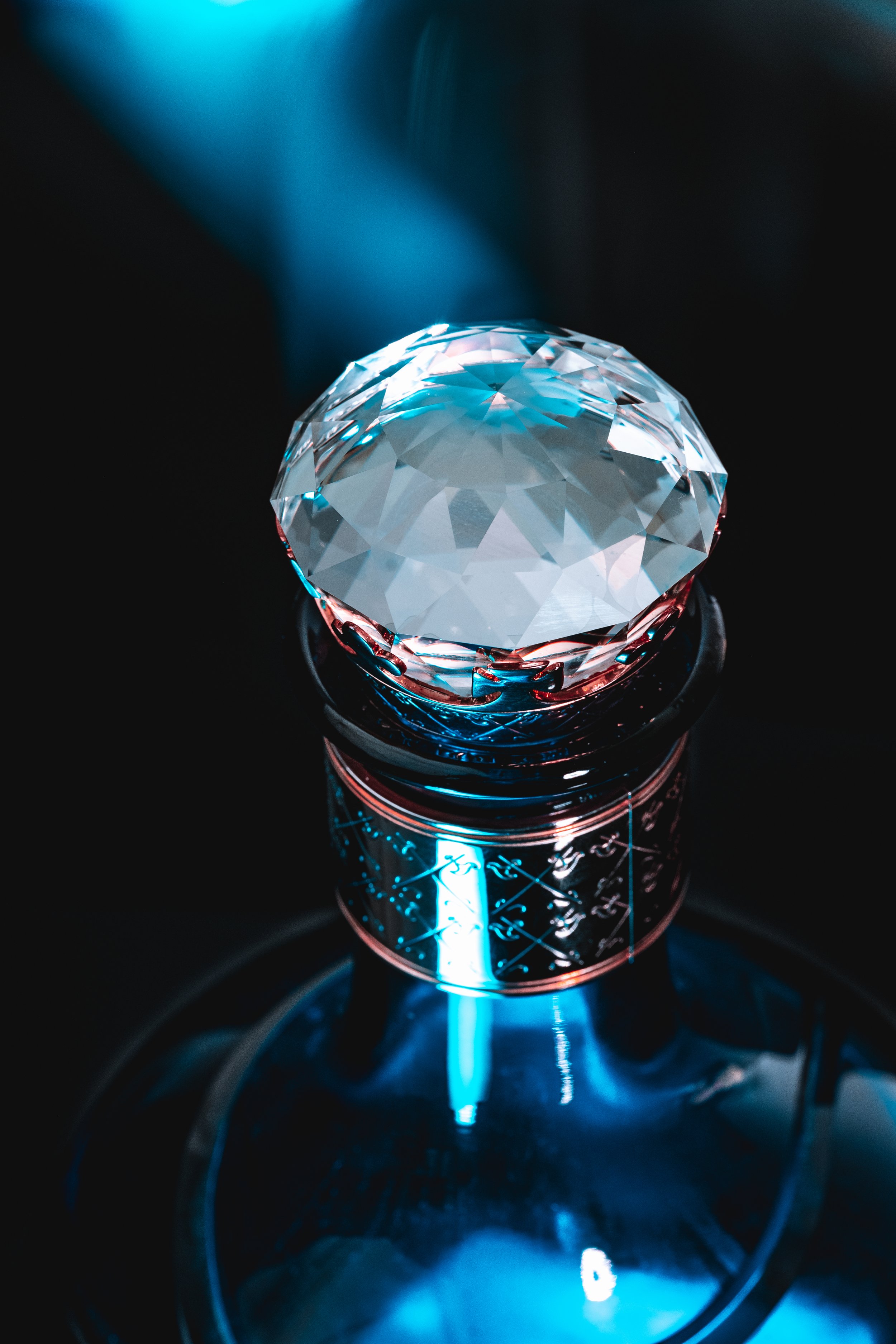

The Heritage Collection

celebrates the treasure of history.

At Lafitte, we know how valuable tradition is:

We recognize the knowledge, values and stories passed on, from one generation to the next, as a rich form of connection and an important part of one’s identity. This intangible legacy deserves to be acclaimed with a fitting stopper.

Created with the most exquisite materials, the Heritage Collection is a pompous celebration of culture and wisdom, and the wealth they offer our lives, rituals and spirits.

Heritage is a whisper of yesteryear in perfect harmony with modern standards, trends and the most upscale materials available.

It allows you to showcase your connection with the past in a contemporary and sophisticated manner that guarantees your brand won’t go unnoticed.

HERITAGE COLLECTION

Our Products

Technical Information

-

DescriptionNatural, multipieces, colmated or agglomerated cork stopper, rounded or chamfered glued to a top (capsule) with hot melt. This capsule can be made of plastic, wood, porcelain, metal, or other materials.

Sizes

27x20mm

27x19.5mm

27x19mm

27x18.5mm

26x19mm

Washing

Washing with a peroxide hydrogen solution, followed by neutralisation, in order to obtain proper disinfection and colour homogenisation. Designation RCP1.

Coating

It can be or not be coated. Water basis coloured coating.

Marking

Marking requested by the client. It may be done using paint or fire for the body and just using fire for the tops. Unless otherwise requested by the client, the registered countermarks RCPi or CR are placed.

Surface Treatment

The surface treatment is carried out in two phases: paraffin and silicone. Designation RCPcap or RCPcsp.

Remarks

Our products and processes comply with the laws and regulations, including the International Code of Cork Stopper Manufacturing Practice and the Portuguese and European legislation for materials and articles intended to come into contact with food.

Packaging

They are packed tightly in LDPE plastic bags with 1.000 cork stoppers, under vacuum, with 0,5 or 1,5 mg/cork stopper of SO2, and placed in cardboard boxes with or without printing.

The amount is usually a box of 3.000 cork stoppers. The cardboard boxes are strapped and/or palletized (wrapped in stretch film). Small amounts can be sent without stretch film.

In the boxes or raffia bags is placed a label with the following information:

— supplier name, customer name, size x class;

— marking (if applicable), lot number, box number, corks amount per box, order number, and other information requested by the client.

When Lafitte Bartop is not responsible for the shipment, another label with the client’s address is placed.

-

DimensionalsStopper Length Nominal value ± 0,5 mm

Stopper Diameter Nominal value ± 0,3 mm

Ovality ≤ 0,5mm

Chamfered/Rounded Nominal value ± 0,5mm

Total height Nominal value ± 0,7mm

Exposed height Nominal value ± 0,5mm

Cap external diameter

— Nominal value ± 0,4mm

— Nominal value ± 0,5mm

Cap height

— Nominal value ± 0,4mm

plastic cap, other materials.

— Nominal value ± 0,5mm

wood cap, other natural materials.Physicals/Mechanicals

Humidity 5% ≤ H ≤ 8%

Absorption ≤ 5%

Dust Content

< 1,5 mg/cork stopper (Flower to 1st);

< 2mg/cork stopper (2nd to 4th and agglomerated bartop);

< 2,5mg/cork stopper (5th,6th and colmated bartop)

Boiling water resistance

— Absence of opening on bonding plan (to multipiece cork stoppers)

— Absence of disintegration (to agglomerated, microagglomerated cork stoppers)

Capillarity < 1 mm

Gluing resistance 100% of cork-covered areaChemicals

Oxidants

— < 0,2 mg/cork stopper - untreated cork stoppers

— 0 mg/cork stopper - treated cork stoppers

2,4,6 - trichloroanisole (TCA) - ≤2 ng /lSensorial

No unusual smells.

Microbiologicals

Number of colonies

≤ 4 UFC/cork stopper -

Intended use

Bartop cork stoppers to close wines, liqueurs, and other alcoholic beverages with the bottle handling in the vertical position.

Validity

The maximum period that cork stoppers should be kept in stock after the treatment date should not exceed 4 months, in appropriate storage conditions.

This is because sulfur dioxide (SO2), used as an antiseptic and antioxidant, declines over time, increasing the likelihood of microbial contamination.

Transportation recommendations

Perform transportation in a closed vehicle, clean, dry, and free of odours. Fluctuations of humidity during transport should be avoided.

Transportation must take preferably cork products, providing that they are free of odours.

It can be transported with other products since they are not toxic and are free of odours.

Storage humidity

The storage relative humidity must be between 40% and 70%.

Storage temperature

The storage temperature must be between 15 ºC and 20ºC.

Other storage recommendations

In the case warehouses don’t present values of moisture and temperature within the recommended ranges, the product should be checked before use.

The cork stoppers should be stored in a dry, clean, and ventilated place and insulated from floors and environments that can somehow transmit odours or flavours. It’s not recommended to use pallets treated with halogenated products – suggestion: heat treatment.

Disinfections should be carried out periodically to all materials that can be a vehicle of contamination. Avoid the use of disinfectants with chlorine.

Treated cork stoppers: once the package is opened, the cork stoppers should be used as soon as possible.If the cork stoppers are not used it is advisable to seal hermetically the bag that contains them and add to it a small amount of an antimicrobial agent such as sulphur dioxide - SO2.

After bottling, during the transport, storage, etc. You should keep the bottles stocked in a vertical position.